My task of

lowering my seat pan was complete but I just couldn't put my old carpet back in the car. A couple of years ago, I had

dyed it black. Also, the carpet pad "jute" backing material was long gone. So, I set about doing some research on which carpet would be the best bet. Back in the 1968, ford had installed nylon cut pile in these cars. Prior to that, they had used an 80/20 (nylon/rayon) loop. However, my research showed that the 80/20 "raylon" proved to be the best fitting and wearing carpet. NPD was the consensus for the best dealer but I had some credit with CJ Pony Parts that I wanted to use plus they were running a 20% sale at the time so, giving into my frugal side, I bought the

ACC Carpet Original Style Molded Convertible 1965-1968 after first e-mailing their sales team to confirm that this was indeed the preferred "Raylon" type of carpet. For the concours aware among my readers, the CORRECT carpet would have been

ACC Carpet Cut Pile Molded Black Convertible 1965-1968.

Regardless of which type of carpet I would have chosen, both were also available with the optional "mass back". This is basically a heavy rubberized compound that is meant to replace the

asphalt underlayment sheets that were used as the car came from the factory. However, I already had the factory style underlayment in addition to

RAAMmat so I opted out of the "mass back" option.

My new carpet had arrived rolled up in a moderately-sized box which I tore open with an eager aggression normally reserved for a medium well sirloin. The carpet unceremoniously plunked out of the box looking fairly pathetic, all rolled-up and wrinkled. I managed to unroll it and separate the front and rear segments, neither of which contained any kind of obvious markings or indication of where the shifter, seat mounting, dimmer switch, etc holes should possibly go.

Upon further inspection, the driver foot pad was rather nice and consisted of a tunnel section that was lacking on my original carpet. The trailing edge of the front segment also sported a nice trim although it was made up of stitching rather than a nylon strip as with my original.

|

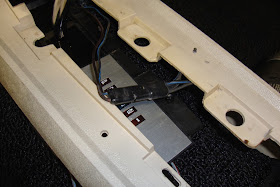

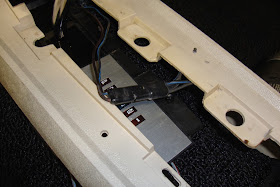

| Carpet Underlayment/sound deadener installed |

|

| A new box has arrived! |

|

| Doesn't look like much. A burrito maybe? An egg roll? |

|

| Ah there it is. |

|

| Nice heel pad. |

|

| A close-up of the loop carpet and front section edging. |

|

| Compared to the old carpet. Note the smaller heal pad and vinyl edging. |

|

| A close-up of the original carpet. Note the difference of the original "cut pile". Also, here's the dimmer switch trim. |

|

| Close-up of the original vinyl edging. |

|

| Original carpet overlaid on the new carpet to mark the shifter hole |

I laid my original carpet over the top of the new after expanding the foot well pockets to determine how closely the cut and fit match and found them to be nearly identical. I then used a white grease pencil to transfer the hole locations from the original to the new carpet although the only hole I cut in earnest was the shifter hole. From there, I fit the front section of carpet into position and then marked the remaining holes for the front seats and the dimmer switch as well as finishing the cut for the shifter hole to extend to all four corners of the shifter housing.

After I felt good about the general position of the front carpet, I laid the edges over the inner rockers and marked lines to the top weld flange of the inner rocker on each side. I then removed the carpet, trimmed it to the marks and laid it back in. However, I didn't make the trim cuts all at once but rather in 2 or 3 test fits taking a little off at a time since I could never put it back. Also, as I was test-fitting, I could more accurately place the location of the dimmer switch hole. I found that the rubber trim for the dimmer could also be removed from the original carpet and fitted to the new. Nice!

UPDATE: 04/07/2015: The consensus in

this VMF thread regarding the dimmer switch grommet is that they were not original to 68's nor was the "cut pile" carpet that came with the car. 68's factory carpet were loop pile with no grommet. So this is the second time that this car has had new carpet installed.

Finally, when I was happy with the placement of the front section, I glued the carpet to the side and top of the inner rocker at each side but pretty much left the carpet loose everywhere else.

|

| Holes transferred from the original carpet. |

|

| Shifter hole cut and front section in for first test fit. |

|

| Checking inner rocker overlap. |

|

| Marked for inner rocker trimming and finish cuts around shifter hole and actual dimmer switch position. |

|

| Driver side inner rocker edge trimmed and original dimmer trim transferred from old carpet. |

|

| Front carpet installed |

The rear section really just needed to be fit under the edge of the front section and then aligned to the foot-well pockets. The seat belt and seat anchor points were then located and cut. I used a box cutter type knife to cut openings for these holes and found the jute padding to be rather difficult to cut through compared to the carpet itself. I'm sure there's a pro method in doing this but I hadn't looked it up at the time. One thing I had read later is that a soldering iron could possibly melt the holes in the carpet a lot easier than cutting them out.

|

| Rear carpet section marked for various hole locations. |

With the carpet laying down on the floor the way I wanted it, I replaced the door sill plates and then worked to install the floor console. I had done this before but failed to take pictures and document the procedure of installing a 68 floor console so here we go!

|

| Wiring is run from the fuse box on the firewall back to the shifter hole. Ground line is attached. |

|

| Shift indicator plate laid upside down with indicator rod (C-shaped stick on the plate) attached to the shift light assembly. |

|

| The shifter stick is fed through the it's hole in the plate and the indicator rod is placed in the shifter eye-hole. |

|

| Shift indicator light plugged into it's connector on the light-feed harness. |

|

| The console base is laid over the shift plate and plugged into it's connector on the light harness. |

|

| The console top is aligned with the indicator plate and the wiring tucked away under the console base. |

|

| The console base is screwed onto the indicator plate. |

I just wanted to write down an extra note here about installing the side tunnel screws. This should be a fairly simple job of drilling holes and then driving the screws down into them but it's anything but simple. The drill will catch the carpet thread and rip a run into it before you realize what's happening and in addition, the carpet backing will pack up the drill bit and extrude itself back out the hole. I had a terrible time with this and finally managed to cut enough carpet and padding away at the screw hole locations to get the task done. So, for anybody else attempting this, THIS is the place to use the soldering iron idea to melt your way through the carpet and maybe burn a hole through the padding. Otherwise, you need to cut clearance for these screws before you permanently fit the front carpet section. What a hassle that would be.

|

| The four side tunnel screws are installed. Read above about how to possibly avoid damaging the carpet here. |

|

| This hole didn't go well. I pulled a run into the carpet. |

|

| The padded top of the console is screwed onto the console base through the rear ashtray opening. |

|

| The padded top is screwed onto the front of the console with two screws as shown here. |

.

|

| Okay, I failed with taking a better pic of this step but see that radio bracket in the middle of the radio opening to the right of the ash tray in the dash? That bracket also has ears that stick down at the sides of the console. The console sides are screwed to that bracket to support the front section of the console base. |

|

| The chrome bezel for the "garage door" and radio assembly is wired into the power and speaker leads in the dash. See those two tabs at the top of the bezel? See those clips behind the bezel in the top of the radio cut-out hole in the dash? Keep those in mind when reading two pictures down. |

|

| The radio/garage door bezel is then inserted and two screws hold it to the base at the lower right and left corners. |

|

| The front bezel pad is snapped onto the bezel and two screws are driven up through the padded front, through two tabs on the top of the bezel and into clips in the dash (remember those from two pics above?) |

Like a cherry on an ice-cream sundae, the T handle can be replaced on the top of the shifter arm thus completing the installation of the console.

After installing the console, the interior kick panels were installed followed by the seat belts, the seats and, finally, the steering wheel.

|

| Install the kick panels |

|

| Install the front seats |

|

| Just a shot to show the new seat level. |

|

| All done! |

At last, the car could once again be taken out on the open road. Let Summer begin!